Controls

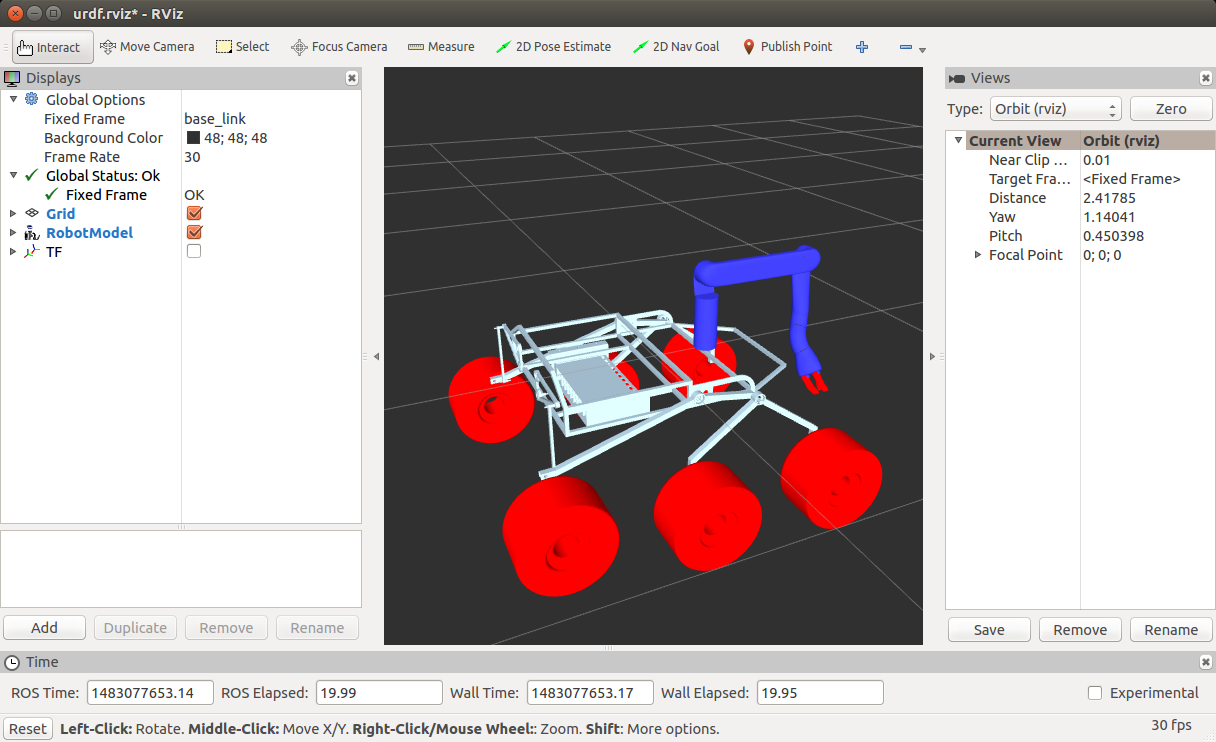

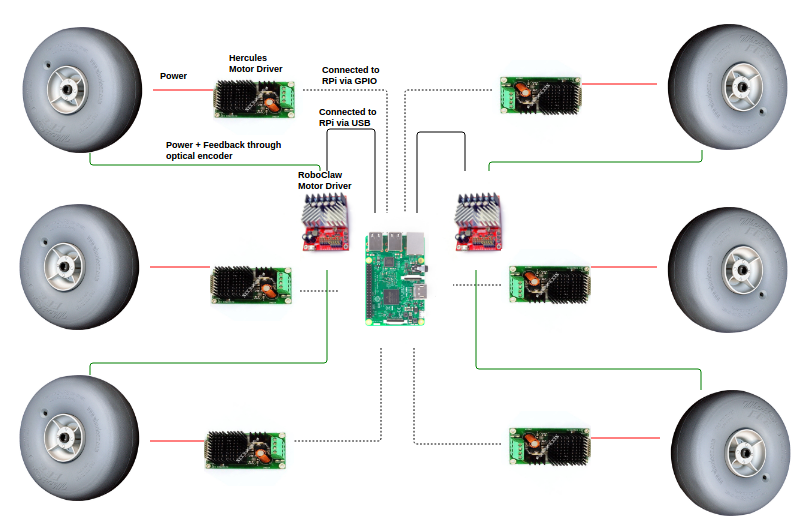

All 6 wheels are driven independently from GPIO pins of Raspberry Pi 3 in open loop, 4 steering wheels (Front and Rear) are steered using closed loop control .Steering is controlled by Roboclaw Motor Drivers onto which we employ a Type II control system, to track ramp input , while drive is controlled by Hercules motor Drivers.

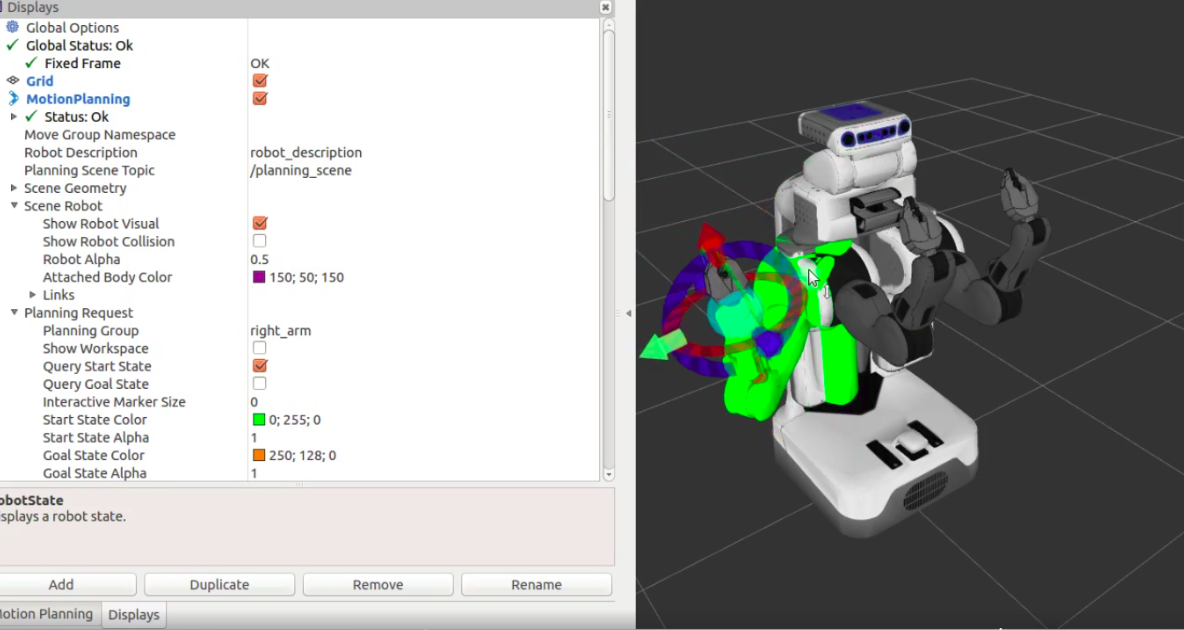

We are working towards getting a state space description of the same, so that we can employ Inverse Kinematics or LQR control for the arm, using Moveit! motion planning plugin .